Takumi Project Aero KIWAMI Bonnet Carbon Version I – VAB VAG VMG WRX STI WRX S4 Levorg

JPY 379,500

Please contact us for availability.

- Genuine Kondo Engineering Takumi Project

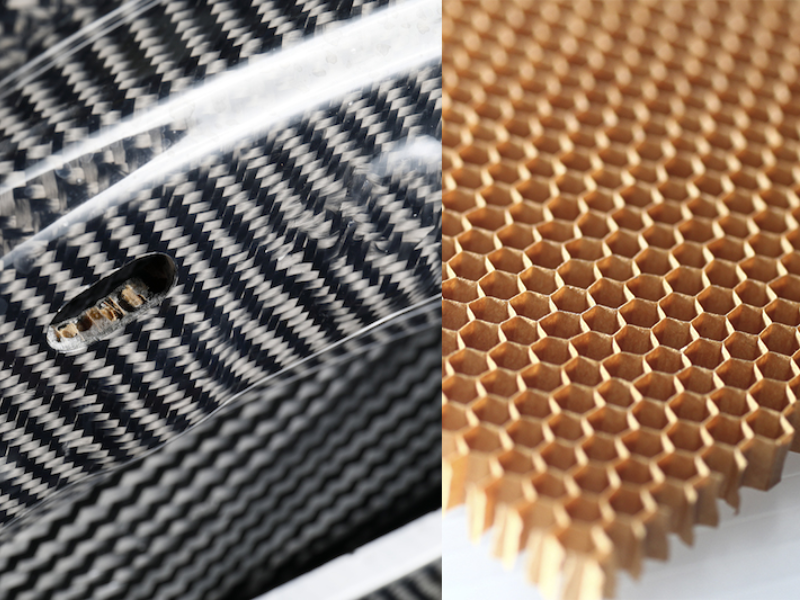

- Material Hard Carbon (H-CFRP)

- Carbon Front and Back

- Version I

SKU: KNDO-CFRP-KIW1Categories: Kondo Engineering

- Lightweight and Strong (HARD CARBON)

- The backbone is made of lightweight and strong hard carbon. Areas where stress is concentrated are reinforced with honeycomb.

- Waterproof design prevents rainwater from entering without a duct cover

Standard carbon and FRP types have the same cooling function and waterproof structure.

The differences between Version I and Version II of the Aero Bonnet for WRX STI/WRX S4/LEVORG

Version II has the design shape of the center duct and mesh (baked paint) on both side ducts.

Other than these two points, the rest of the car is basically the same, including the back side.